| Device Name: | High efficiency boiling granulator |

| Equipment type: | QFN-BY-300 (customized) |

| Rated capacity: | MAX. 300g/batch (support customization) |

| Test machine: | Support the test machine to do the experiment |

| Scope of application: | Various granules and pellets, etc. |

| Applicable scenarios: | Scientific research, chemical industry, food, pesticide, medicine and biological industry in Universities |

| Is it guaranteed? | Three-year National Warranty |

| Consultation telephone: | 17317246351 |

One.Product introduction:

The small scale boiling fluidized bed granulator (micro boiling granulator) is a small multifunctional granulating and coating equipment developed by our company. It has the advantages of small volume, low material handling capacity and convenient preparation, and can be used for mixing, drying, granulation and coating of various pellets and pellets. The equipment also has spray drying function to meet the needs of universities and scientific research institutes. At present, nearly more than 500 universities in China have adopted the spray granulation equipment of our company.

Two.Product structure:

The multi-function spray granulation machine top spray device is composed of a conical pot body and expansion chamber. Because the pot body is cone-shaped, the fountain type fluidization state is ensured, and the inlet air flow drives the material in the pot to enter the expansion chamber upward. In the pot body and expansion indoor movement. There are several nozzle mounting ports on the top of the expansion chamber, which can be used for spraying atomized liquid during granulation and coating. Top spraying can be used in drying, granulation and masking coating.

The bottom spraying device of a multi-function spray granulator is composed of a conical pot body and a built-in draft tube. The bottom of the pot body adopts a double air inlet structure to control the flow state inside and outside the draft tube. Material moves upward at high speed in the draft tube, enters the expansion chamber and falls out of the draft tube, thus circulating. The atomizing spray gun is installed in the center of the draft tube. The spray gun sprays liquid from bottom to top in the same direction as the material and air flow. Bottom spraying is mainly used for functional coating of various pellets and fine particles.

Three.Technical characteristics:

1) the multi-function spray granulation machine is easy to operate: the control system adopts PLC automatic control, and the color touch-screen operation. The experimental parameters such as inlet air temperature, air temperature, material temperature, fan speed and spray pressure during the experiment can be changed immediately according to the experimental needs and convenient for users. The touchscreen has USB interface, and the data can be exported to U disk or online printing.

2) Stable operation: Imported equipment is used in the core components of the equipment, such as touch screen, fan, heater and control system, which ensures the stability and reliability of the equipment.

3) the multifunctional spray granulator can replace the pan with different volume to meet the experimental needs of different batch materials.

4) Feedback function of material temperature and air temperature linkage to ensure the realization of the best process;

5) the multi-function spray granulator adopts a new blow back system to effectively improve the granulation yield.

6) in order to meet the requirements of users in adjusting the parameters in the experimental range, the multi-function spray granulation machine adopts real-time control PID constant temperature control technology in the design of temperature control, so that the temperature control in the whole temperature zone is accurate, and the temperature is stable in the process of granulation and coating.

Four.Overview of working principle:

Spray agglomeration in fluidized beds is a molding method that can enhance the properties of powders. By spraying in a fluidized bed system, we can transform the powder, non fluidity, and generally poorly soluble particles into free flowing large particles with excellent solubility. The method is especially suitable for preparing tablets, detergents, drinking powder and instant products.

Fluidized bed spray agglomeration and granulating can move tiny powder particles on the fluidized bed, and spray them to bind solution or suspension to produce liquid bridges to form aggregates. Continue spraying until the aggregate reaches the required size. When the capillary and residual water evaporate on the surface, a hollow space is formed in the particles, and the hardened adhesive makes the new structure solidify thoroughly. Lack of kinetic energy in fluidized beds can result in extremely porous structures with a large number of capillaries. Aggregates usually range in size from 100 microns to 3 millimetres, while starting materials can be ultrafine.

Fluidized bed drying - Granular controlled drying is an effective solution (multi-function spray granulator) fluidized bed drying is the best way to control wet, dry, soft and uniform drying. The intense heat/mass exchange of fluidized bed products makes this method particularly effective and time-saving. The technology is also suitable for post-drying of spray-moulded and extruded products with very low residual moisture.

Fluidized bed drying can be used in the whole powder processing industry. In the pharmaceutical industry, this innovative approach has long replaced time-consuming tray drying: using fluidized bed drying technology can reduce drying time in drying ovens by about 20 times. In addition, compared with non-uniform tray drying, fluidized bed drying can provide controlled and uniform drying conditions.

Whether the product is produced in fluidized bed or high shear mixer, whether in batch or continuous production: drying through fluidized bed must ensure that drying is always carried out in thermodynamic equilibrium. The inlet temperature must be chosen so that the water transported from the inside of the particle to the surface through the capillary tube can evaporate from the surface of the particle. If the inlet temperature is too high, it is likely to form a surface shell, which will hinder or even prevent moisture from being transported from deeper layers to the outside. This will delay the drying process rather than accelerate it.

For spray granulation, spray agglomeration or spray process, it should be noted that not only the moisture needs to be evaporated until the defined residual value is reached, but also the drying process is carried out throughout the spraying process. High inlet temperature may lead to insufficient liquid bridge, unstable particle structure and uneven appearance of film. Under reasonable use, fluidized bed drying can provide efficient solutions, bringing soft and uniform drying to your products.

Five.Principle of granulation:

The coating principle of multi-function one step granulator for spray granulation coating machine: the bottom spraying device is an important breakthrough in coating technology, making it possible to coat small particle materials. With the development of technology, powder as small as 50 m can be coated. Bottom spraying device consists of a conical pot body and a draft tube. The bottom of the pot body adopts a double air inlet structure to control the air flow inside and outside the draft tube. Material moves upward at high speed in the draft tube, enters the expansion chamber and falls out of the draft tube, thus circulating. The spray head atomized droplets from top to bottom in the center of the draft tube, and the droplets spread evenly on the surface of the particles to form a small film. During this process, the thickness of the coating film increased steadily and dried to the completion of the coating.

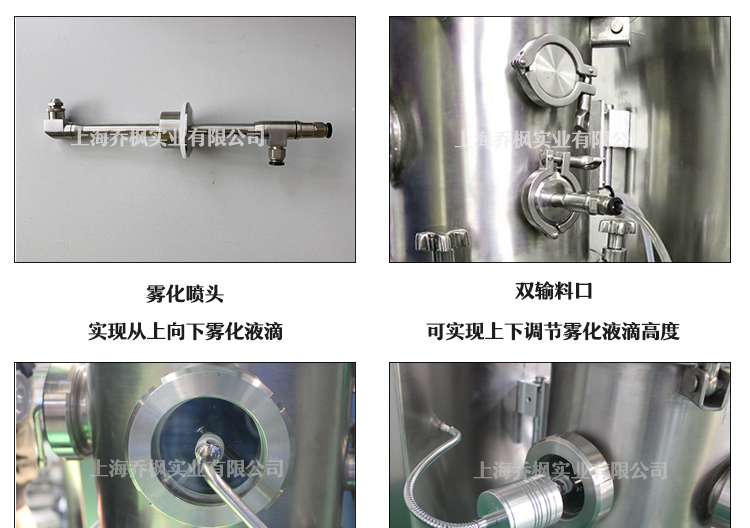

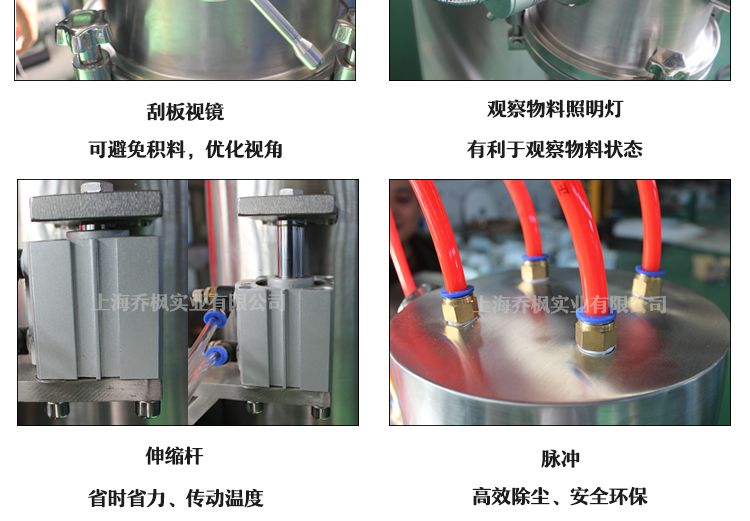

SixEquipment details:

Seven.Applications:

Pharmaceutical products / food and fodder / ceramic products / plastics, rubber / polymers and resins / biochemical products / chemicals and fertilizers / perfume / pigments and dyes / vegetables and plant extracts / aromatic / food crops and so on.

Eight.Equipment parameters:

|

Serial number |

Model |

QFN -BY -300. |

QFN -BY -1000. |

QFN -BY -3000. |

|

One |

function |

Boiling granulation/coating |

Boiling granulation/coating |

Boiling granulation/coating |

|

Two |

Rated treatment of spray granulation |

MAX 300g /batch |

MAX 1000g /batch |

MAX 3000g /batch |

|

Four |

Minimum amount of spray granulation |

50g |

50g |

150g |

|

Five |

drying temperature |

40 -15008304C |

40 - 150 |

40 -15008304C |

|

Seven |

compressed air |

7Bar |

2-4 Bar |

2-4 Bar |

|

Eight |

Temp Accuracy |

2 -8304C |

Number |

2 -8304C |

|

Nine |

Coating |

MAX 300g /batch |

50-1000g/batch |

MAX 3000g /batch |

|

Ten |

blend |

MAX 300g /batch |

50-1000g/batch |

MAX 3000g /batch |

|

Eleven |

Spray head type |

Two fluid |

Two fluid |

Two fluid |

|

Twelve |

injector |

0.7mm standard (1.0mm available) |

0.7mm standard /(0.5 /0.75 /1.0 /1.5 /2.0mm available) |

0.7mm standard /(0.75 /1.0 /1.5 /2.0mm available) |

|

Thirteen |

Fan |

0-150 m?/h |

0 to 150 m3 / h |

0-150 m?/h |

|

Fourteen |

Peristaltic pump |

Max. 1000ml/h |

Max. 1500ml/h |

Max. 5000ml/h |

|

Fifteen |

Drying chamber |

5L |

10L |

30L |

|

Sixteen |

heater |

3KW |

3KW |

10KW |

|

Seventeen |

Drying room material |

SUS304 stainless steel |

SUS304 stainless steel L & high borosilicate glass |

SUS304 stainless steel |

|

Eighteen |

Rack material |

SUS304 stainless steel |

SUS304 stainless steel |

SUS304 stainless steel |

|

Nineteen |

Seal ring |

Pneumatic |

Silica gel |

Pneumatic |

|

Twenty |

noise |

<60db |

<60db |

<60db |

|

Twenty-one |

size |

1150mm 700 * 600 * |

900*800*1300mm |

2290mm to 1180. |

|

Twenty-two |

weight |

135KG |

200KG |

260KG |

|

Twenty-three |

Operation mode |

Automatic/manual |

Automatic/manual |

Automatic/manual |

|

Twenty-four |

display |

7-Inch LCD display with USB interface |

7-Inch LCD display with USB interface |

7-Inch LCD display with USB interface |

Tel: 17317246351

Mailbox: sales@qfn17.com

URL: http://www.sddgrl.com.cn

Address: Shanghai fengxian canal north road no. 1185